INTERNAL

|

Hand-operated Potter's Wheel in Ancient Greece Eleni Hasaki School of Anthropology Prof. Eleni Hasaki and students in her classes have collaborated to build and operate a replica of an Ancient Greek potter's wheel. A number of professional potters have tested it and their times for completing various stages in the forming process have been recorded. For a UA story on this project click here The ceramics community is welcome to use the wheel and test its capacities and limitations. Please contact Prof. Eleni Hasaki to arrange a meeting (hasakie@email.arizona.edu) |

EXTERNAL

|

|

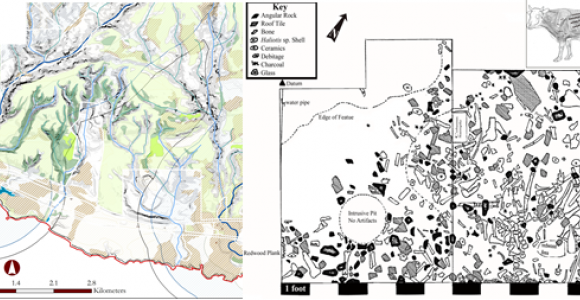

Acorn Oil Rendering and the Adoption of Pottery in the Upper Great Lakes Kelsey Hanson School of Anthropology As an abundant and easily storable source of fats and carbohydrates, acorns represent a significant, yet often overshadowed, element of the human diet. Hanson’s recent research in the Laboratory for Traditional Technology (2017) has sought to add one more product to the acorn’s growing resume: oil. Acorn oil would have provided a nutritionally rich product for overwintering and may have been an important impetus for adopting pottery in the region. Organic residue analysis of pottery sherds from two Woodland period sites on Grand Island, Michigan yielded lipid profiles consistent with nut oil (Skibo et al. 2009). Skibo et al. (2016) have since argued that the adoption of pottery in the Upper Great Lakes region was intended to facilitate acorn oil rendering, largely replacing stone boiling techniques as the predominant cooking technology. While ethnographic sources confirm that oil was rendered from acorns (e.g. Densmore 1928), the mechanics of this process had not been systematically investigated. Hanson’s research sought to evaluate this argument by establishing experimental parameters for rendering acorn oil. Put simply, does simmering in ceramic vessels offer a more efficient mechanism for rendering oil than stone boiling techniques? Read more |

|

Understanding Early Pottery in Petrified Forest National Park Bill Reitze, School of Anthropology In Summer 2016 Bill Reitze (Petrified Forest National Park; Recipient of the John L. Cotter award for excellence in scientific archaeological research, community involvement, and public education) borrowed the LTT ceramic Neycraft oven which helped him and his team conduct refiring experiments in order to gain a better understanding the early pottery in Petrified Forest National Park. He kindly submitted the following report to us. Read more |

|

|

Consequences of Large-Scale Forging Activities on the Osaka Plain in the Fifth Century AD James Scott Lyons UC Berkeley (Fall 2015) Prior to advancing to candidacy at my home institution of UC Berkeley, I came here to learn metallographic specimen preparation and interpretation with Professor Killick, who has been extremely generous in sharing his time and resources. I will apply what I’ve learned here to investigate possible environmental consequences of large scale iron forging activities on the Osaka Plain in the fifth century AD. In the meanwhile, I’ve been cutting my teeth on a number of samples I picked up last summer. Using a mix of Japanese antiques, recent tools made from antique wrought iron, and some made of modern steels, I’ve been able to observe a wide variety of composite structures as well as metal microstructures. While I still have a lot to learn, I’m planning on submitting a poster presentation to the 8th World Archaeological Congress based on my metallographic interpretation of a 15th century Bizen-school Japanese sword. To get all this done, I’m splitting my time between the LTT, where I polish (and repolish) my specimens, and the multipurpose lab (Haury 411) where I make use of the microscopes to investigate their microstructures. I’m only here until the end of December, but I’m grateful for the support and kindness of the School of Anthropology and especially the users of the LTT.

|

|

|

Experimental Seed Grinding Session: Need for Volunteers Dr. Tammy Buonasera (Fall 2015, Spring 2016) Participate in a set of NSF-funded experiments and gain first-hand experience using a variety of milling tool designs--from large basalt mortars to shallow sandstone grinding slabs. Each volunteer will process wild grass seeds or acorns into flour over two, non-consecutive, 30-minute segments and record observations. Results provide some of the empirical information needed to formally model interactions between tool morphology, raw material choice, product output, wear rates, and overall labor costs. Results will also supply information vital for interpreting patterns of use-wear and for sampling organic residues. These and other grinding sessions are part of a larger project aimed at evaluating relationships between hunter-gatherer milling tool designs, mobility, and resource use. |

|

|

. In Search of the Origin of Korean Iron and Bronze Technologies Prof. Jang Sik Park Department of Metallurgical Engineering, Hongik University in Korea) Visiting Scholar at the School of Anthropology "In his comments on my report summarizing the results of the metallographic examination of iron artifacts from a royal tomb in Gyongju, Korea, constructed in mid 5th century AD, John Verhoeven, my former advisor at Iowa State University said to me, “was the iron technology, based on the use of bloomery smelting and steelmaking by carburization, practiced in your country?” At the time, I did not realize his question was concerned about the origin of Korean iron technology, which, based on his knowledge, should be China. He found in my report, however, evidence in clear contrast to his expectation. Ever since I have been spending most of my time searching for alternative routes for technological transmission to the Korean peninsula, in close collaboration with archaeologists working in Mongolia, Central Asia, India and Indonesia. My research in the last 16 years has led me to believe that the interaction sphere in antiquity may have been much more extensive and complicated than could be inferred from the data currently available. I have identified some evidence supporting this new interpretation, thanks mainly to the support from many collaborators and advisors. I am now engaged in testing the theory viewing Chinese influence on the Xiongnu development in Mongolia as much less critical than previously proposed. Read more |

|

PROFESSOR MICHAEL B. SCHIFFER'S PUBLICATIONS:

Johnson, J. S., J. Clark, S. Miller, V. D. Robins, M. B. Schiffer, and J. M. Skibo. 1988. Effects of firing temperature on the fate of naturally occurring organic matter in clays. Journal of Archaeological Science 15:403-414.

Mabry, J., J. M. Skibo, M.l B. Schiffer, and K. Kvamme. 1988. Use of a falling-weight tester for assessing ceramic impact strength. American Antiquity 53:829-839.

Schiffer, M. B. 1988.The effects of surface treatment on permeability and evaporative cooling effectiveness of pottery. In Proceedings of the 26th International Archaeometry Symposium, edited by R. G. V Hancock, R. M. Farquhar, and L. A. Pavlish, pp. 23-29. Archaeometry Laboratory, Department of Physics. University of Toronto, Toronto.

Schiffer, M. B. 1990.Technological change in water-storage and cooking pots: Some predictions from experiments. In The changing roles of ceramics in society: 26,000 B.P. to the present, edited by W. D. Kingery, pp. 119-136. American Ceramic Society, Westerville, Ohio.

Schiffer, M. B. 1990.The influence of surface treatment on heating effectiveness of ceramic vessels. Journal of Archaeological Science 17:373-381.

Schiffer, M. B. 2003. Properties, performance characteristics and behavioural theory in the study of technology. Archaeometry 45:169-172.

Skibo, J., M. T.C. Butts, and M. B. Schiffer. 1997. Ceramic surface treatment and abrasion resistance: an experimental study. Journal of Archaeological Science 24:311-317.

Schiffer, M. B., and J. M. Skibo. 1987. Theory and experiment in the study of technological change. Current Anthropology 28:595-622.

Schiffer, M.B., and J. M. Skibo. 1989. A provisional theory of ceramic abrasion. American Anthropologist 91:101-115.

Schiffer, M. B. and J. M. Skibo. 1997. The explanation of artifact variability. American Antiquity, 62:27-50.

Schiffer, M.B., J. M. Skibo, T. C. Boelke, M. A. Neupert, and M. Aronson. 1994. New perspectives on experimental archaeology: surface treatments and thermal response of the clay cooking pot. American Antiquity 59:197-217.

Skibo, J. M., and M. B. Schiffer. 1987. The effects of water on processes of ceramic abrasion. Journal of Archaeological Science 14:83-96.

Skibo, J. M., and M. B. Schiffer. 1995. The clay cooking pot: an exploration of women's technology. In Expanding archaeology, edited by James M. Skibo, Axel Nielsen, and William Walker, pp. 80-91. University of Utah Press, Salt Lake City.

Skibo, J. M., M. B. Schiffer, and K.C. Reid. 1989* Organic tempered pottery: an experimental study. American Antiquity 54:122-146.

Vaz Pinto, I. M. B. Schiffer, S. Smith, and J. M. Skibo. 1987. Effects of temper on ceramic abrasion resistance: a preliminary investigation. Archeomaterials 1:119-134.